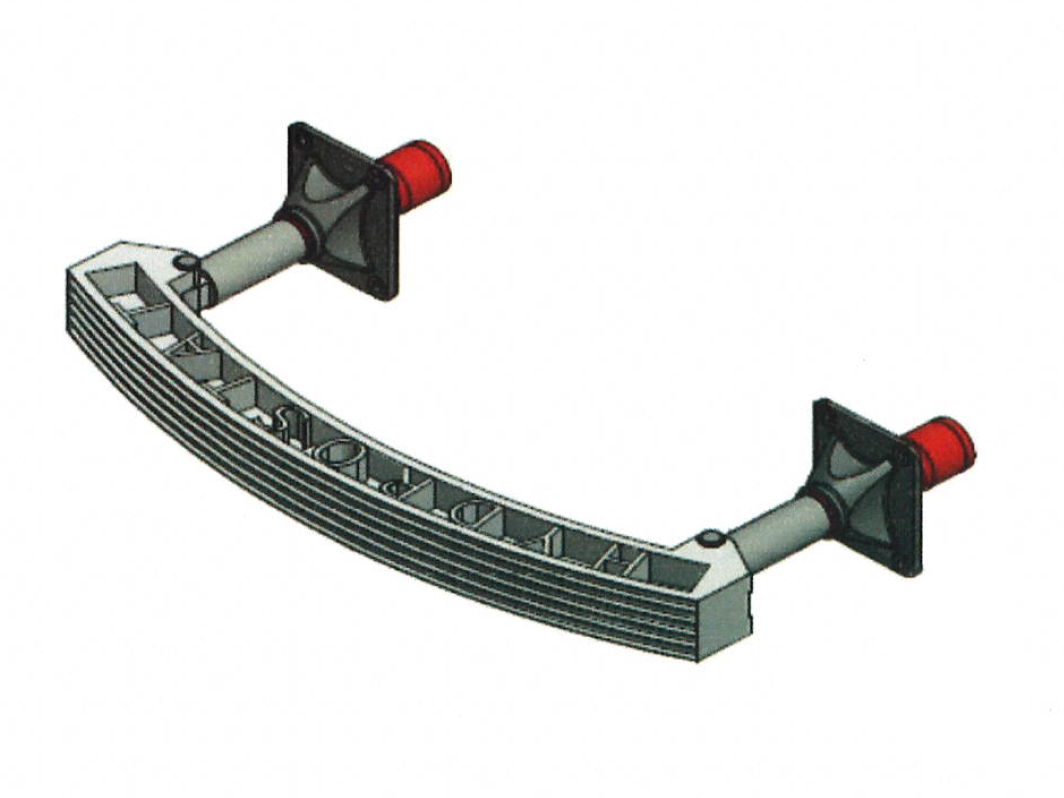

Coupling buffers, buffers for front and rear bars, destructive deformation elements

Transport companies around the world rely on HYDROSTAT. We develop and manufacture shock absorbers for automatic and semi-permanent couplings and for the fronts of underground trains and trams.

HYDROSTAT coupling buffers are used to protect against impacts when shunting or coupling vehicles and – depending on the vehicle mass and configuration – can safely absorb impacts at collision speeds of 25 km/h and more.

HYDROSTAT buffers are used simultaneously as energy absorbing and support elements on the front and rear bars of trams and underground trains.

Our destructive energy absorbers can be operated in combination with HYDROSTAT buffers, for example, or as sole protective elements in the form of emergency safety devices.

Rail applications – our products:

Coupling buffers

- Regenerative: Automatic return to starting position, no replacement following impact

- Pre-tensioned: High actuation force, controlled energy distribution

- Variable: In line with force/displacement characteristics (linear,

progressive, almost horizontal or degressive) - Working method: With compression, with tension or with compression and tension; available with or without guide tube

Buffers for front and rear bars

- Regenerative: Automatic return to starting position, no replacement following impact

- Individual: In line with force/displacement characteristics

- Working method: Usually with compression, with tension also possible; available with or without guide tube

Destructive deformation elements

- High energy absorption

- Compact design

- No pre-tensioning device

- No return mechanism

- Low-maintenance

- Behaviour ranging from speed-sensitive to virtually speed-independent

- Also used in combination with deformation tube, deformation cartridge or deformation bellows

The hydrostatic principle

HYDROSTAT shock absorbers protecting lifes and values since 1995. We offer a complete range of services – from consulting thru development till manufacturing and testing.

Your personal contact

We are pleased to serve you: from HYDROSTAT you can expect well-founded consulting service that is focused on you and your project.

Talk to us: Tel .: +49 2366 9383311.