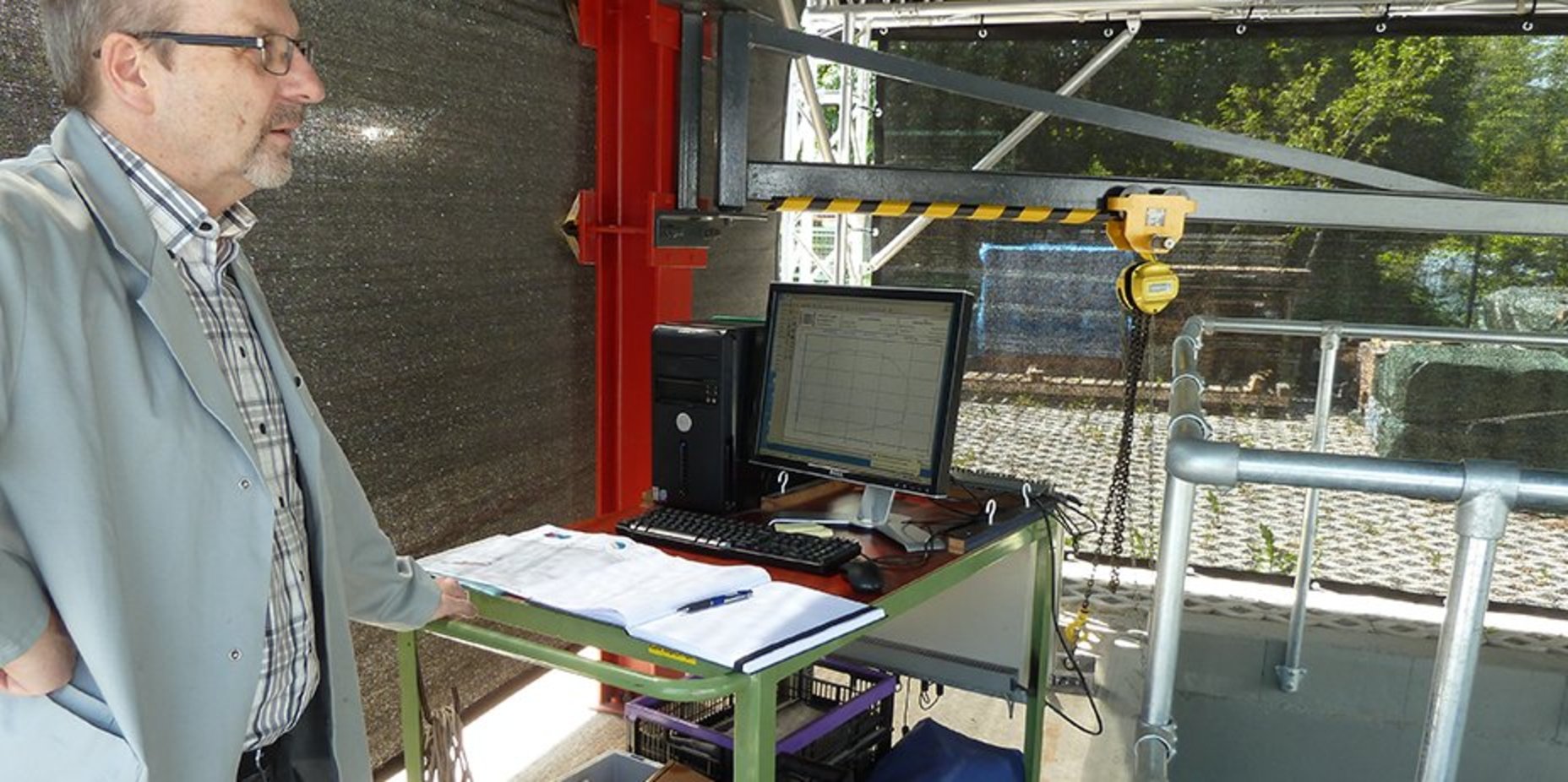

Static tests, dynamic collision tests and computer-controlled endurance tests

At Hydrostat, quality assurance is an ever-present topic: Our company headquarters in Herten is equipped with comprehensive in-house testing equipment. We carry out static tests, dynamic collision tests and computer-controlled endurance tests here.

We also carry out non-destructive material testing: This includes surface crack tests using magnetic powder and ultrasound tests for areas under high loads.

Our dynamic test rig was designed for a maximum load of 80 tonnes and features a track length of 44 metres. As the measurement equipment is covered, all tests can be carried out regardless of the weather conditions. The installed incline allows for a maximum collision speed of around six metres per second.

The hydrostatic principle

HYDROSTAT shock absorbers protecting lifes and values since 1995. We offer a complete range of services – from consulting thru development till manufacturing and testing.

Your personal contact

We are pleased to serve you: from HYDROSTAT you can expect well-founded consulting service that is focused on you and your project.

Talk to us: Tel .: +49 2366 9383311.